RUST OLEUM 3333 SUPER ADHESIVE PRIMER

RUST OLEUM 3333 SUPER ADHESIVE PRIMER is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

RUST OLEUM 3333 SUPER ADHESIVE PRIMER

Excellent adhesion on smooth & dense substrates.

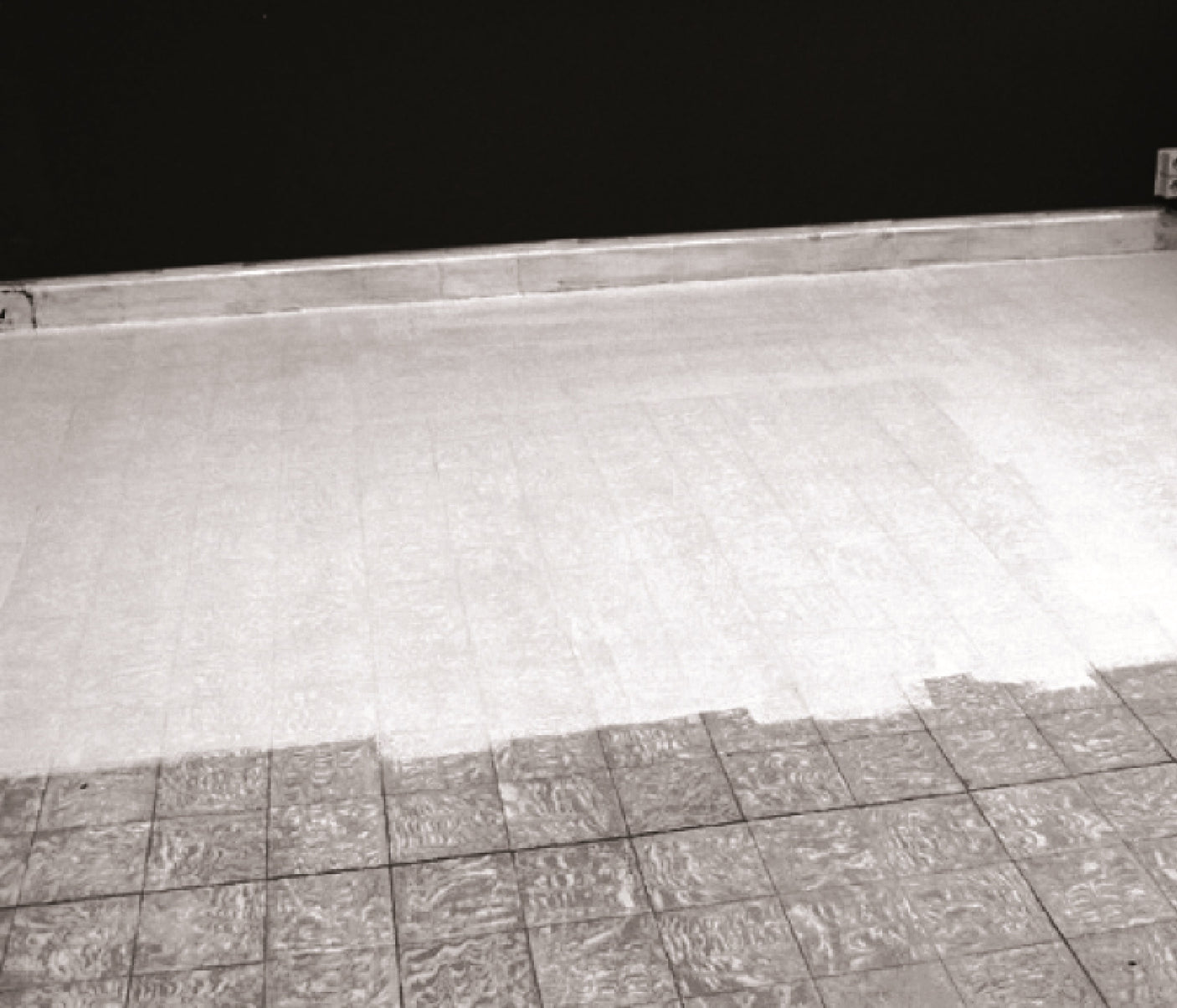

Water-based epoxy primer for use on smooth floors, like power-floated concrete and tiles

- Perfect chemical bond without blasting or etching

- Low material usage - A real cost saver

- Can be recoated with virtually any other 2K paint

- Water-based; low odour

- Excellent flow

RECOMMENDED USE

Super Adhesive 3333 should be used on non-porous, dense mineral substrates like tiles or power floated concrete; non-ferrous metals like stainless steel, aluminium or new hot-dip galvanized steel and thermosetting plastics like fibreglass-reinforced polyester or epoxy. Resists light to moderate abrasion, intermittent high humidity and moisture, regular chemical cleaning and spillage of chemicals if recoated with the appropriate RUST-OLEUM System; can be recoated with practically all RUST-OLEUM Epoxy, Polyurethane, Chlorinated Rubber/Vinyl and Acrylic coatings. Classified Class 1 Surface Spread of Flame according BS 476; part 7: 1987.

DRY TIMES BY 20º C/RH 50%

- Touch dry: 6 hours

- Dry to handle: 8 hours

- Dry to recoat: 16 hours (20°C), 24 hours (10°C), 12 hours (30°C) but within 72 hours

- Fully cured: 8 days

- Pot Life: 2 hours

PRACTICAL CONSUMPTION

25-30 m²/l. Apply in a very thin layer not more than 25 μm wet (15 μm dry).

SURFACE PREPARATION

Remove grease, oil and all other surface contaminations with RUST-OLEUM FK 111 Cleaning Solution or by alkaline or high pressure (steam) cleaning. New concrete should cure and dry for at least 30 days prior to the application of the coatings. The surface must be clean and may be slightly damp during application.

DIRECTIONS FOR USE

Stir individual components thoroughly before mixing them together. Use the boxing method or a low speed mixer.

APPLICATION CONDITIONS

Temperature of air and substrate between 10 and 35°C and relative humidity below 70%. The substrate temperature must be at least 5°C above dew point.

APPLICATION & THINNING: BRUSH

Always dilute with 20% volume with water. Use brushes based on a mixture of synthetic/natural bristles. Check wet film thickness, avoid excessive film thickness. Preferably use disposable brushes.

APPLICATION & THINNING: ROLLER

Always dilute with 20% volume with water. Use HD foam roller. Check wet film thickness, avoid excessive film thickness. Preferably use disposable rollers.

APPLICATION & THINNING: AIR-ATOMISED SPRAY

Up to 20% volume with water. Spray: Gravity cup and pressure cup. Tip size: 1.2 -2.0 mm. Atomizing pressure: 2 - 4 bar. Check wet film thickness, avoid excessive film thickness.

CLEANING OF EQUIPMENT / SPILLS

Immediately after application with (hot) water and soap.

REMARKS

Do not try to apply a hiding coat to avoid adhesion issues and water sensitivity. If the relative humidity is high during drying, curing might be retarded.

Made by: